Hot bent glass is a curved glass made by heating and softening flat glass, bending and annealing it in a mold, which combines aesthetics and functionality.

1、 Core Process and Classification

• Process principle

(1) Heating softening: Heat the flat glass to the softening point of 600-650 ℃ and shape it by self weight or mold pressure;

(2) Annealing treatment: Slowly cool down to below 280 ℃ to eliminate internal stress and avoid self explosion in the later stage.

•Bending type

|

Type |

Technical difficulties |

Typical application scenarios |

|

Single bend |

Insufficient adhesion at the edge of the curve |

Building doors and windows, curved curtain walls |

|

bend |

Easy to show mold marks at corners/curved straight edges |

Glass counter, aquarium |

|

Composite bending |

High precision molds and professional equipment are required |

Spherical decoration, arched corridor |

2、 Performance characteristics

|

Indicator |

Parameters/Characteristics |

Compared to ordinary glass |

|

impact resistance |

Can withstand the impact of a 1040g steel ball at a height of 1 meter without breaking |

Ordinary glass is fragile |

|

bending strength |

≥ 200MPa (tempered hot bending version) |

Ordinary glass ≤ 70MPa |

|

safety |

Broken into non angular particles after tempering |

Non tempered steel has a risk of cutting |

|

Degree of freedom in design |

Customizable irregular surfaces without connecting ports |

Limited to flat or simple radians |

Note: Tempered hot bending glass combines safety and high strength, but ordinary hot bending glass has lower strength and is only suitable for decorative scenes.

3、 Application scenarios and selection

• Construction field

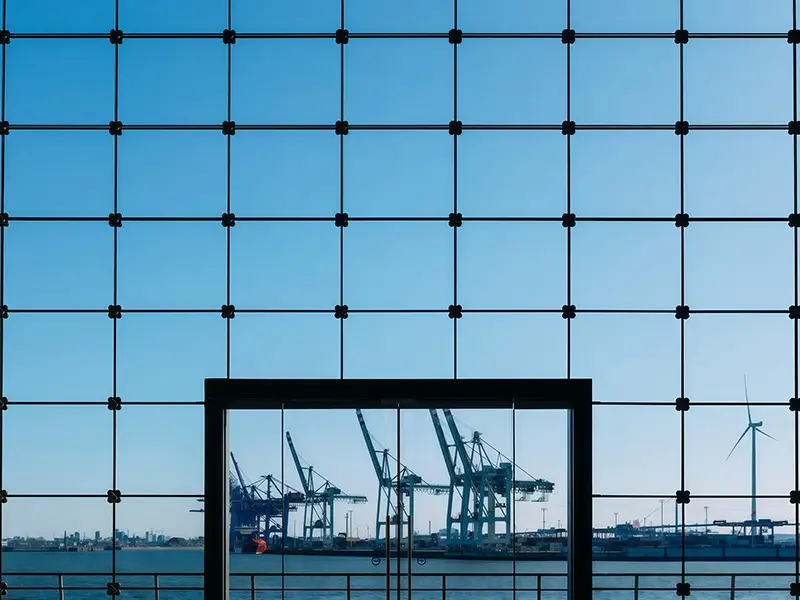

(1) Curtain wall and skylight: Composite curved glass creates a streamlined appearance, with customizable light transmittance;

(2) Arched corridor/sightseeing elevator: Single curved or bent glass enhances the sense of spatial extension.

• Home and Business

(1) Fish tank: ≤ 80cm small tank (large tanks are prone to bursting due to water pressure);

(2) Glass furniture: coffee table, washbasin, artistic decoration (tempered steel to ensure safety);

(3) Commercial display: curved counter, mirrored wall (transparency>70% to ensure display effect).

• Technological upgrade direction

(1) Hot bendable coated glass: In 2025, the new double silver coated glass supports hot bending, balancing insulation and curved surface design;

(2) Intelligent integration: curved glass combined with dimming/power generation functions, suitable for low-carbon buildings

4、 Installation

• Selection suggestions

(1) Tempered hot bending glass with a thickness of ≥ 6mm must be selected for pressure bearing scenarios such as fish tanks and curtain walls;

(2) The large-scale curved surface priority continuous hot bending furnace technology for construction ensures uniform heating.

5、 Process Trends

(1) Mold Innovation: The precision of graphite molds has been improved to 0.01mm, supporting complex free-form surfaces;

(2) Energy saving: The continuous hot bending furnace at the workstation reduces energy consumption by 40% and improves mass production efficiency.

Bent glass

Category:

GLASS ENCYCLOPEDIA

Can frosted glass be cleaned with wet wipes?

→ Okay! Recommend using glass cleaner and fish scale cloth to avoid scratching the matte layer with hard objects.

How to choose between single-sided frosted and double-sided frosted?

→Single sided frosted (smooth surface facing inward) is easier to clean; Double sided frosted provides stronger privacy.

Will frosted glass reduce light transmittance?

→ It will decrease by about 20% -40%, and the ultra white glass substrate can reduce the loss of light transmission.

What are the common glass products in daily life?

Get A Quote

We will contact you within one working day. Please pay attention to your email.

Related Products