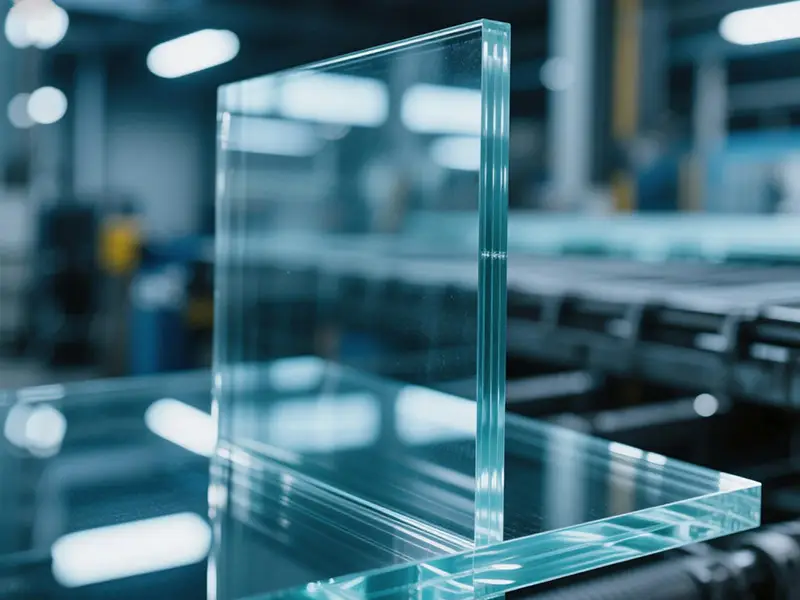

Silk, wire, and painted glass are special decorative glasses formed by sandwiching metal wires, silk fabrics, or artistic patterns between glass layers through EVA/PVB film composite technology, which combines safety and artistry.

1、 Core definitions and process comparisons of wire, silk, and painted glass

Process commonality: All require tempering treatment (safety mandatory), and the interlayer thickness is usually 5+5mm or 6+6mm.

|

Type |

Embedded material |

Process characteristics |

Visual effects |

|

wired glass |

Metal wire mesh (iron wire/copper wire/stainless steel wire) |

Glass softening state pressed into metal wire, high-temperature extrusion molding |

Grid texture, strong industrial feel |

|

Laminated glass |

Silk/fabric (silk/non-woven fabric) |

Double layered glass with EVA film and silk, laminated composite |

Softening light, ink blending effect |

|

Clip painted glass |

Printing patterns/landscape painting film |

Customized image sandwiching adhesive layer, vacuum hot pressing |

Clear patterns (such as new Chinese landscape) |

2、 Core performance and scene adaptation

1. Functional characteristics

Safety: After rupture, the fragments are adhered by wire mesh/adhesive layer, with no risk of splashing (in accordance with GB 15763.2 "Safety Glass for Building Use");

Fireproof: The laminated glass can block the spread of flames (fire resistance limit>1 hour);

Decorative: The transmittance of the laminated glass is 70% -93.7%, creating a hazy light and shadow.

2. Application scenarios

|

Type |

Typical scenario |

Representative case |

|

wired glass |

Anti theft doors and windows, fireproof partitions, industrial plants |

Hotel fire compartment |

|

Clip silk/clip painted glass |

New Chinese style screen, foyer background wall, scenic area decoration |

Landscape painting screen (transparent but opaque) |

|

Composite function |

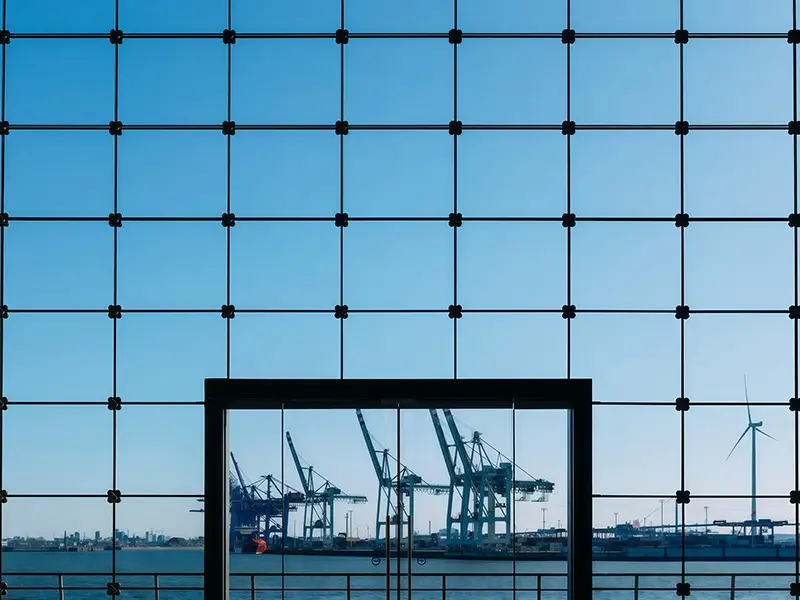

Hollow+silk structure (insulation ↑ 40%) |

Energy saving art curtain wall |

3、 Quality identification

Wire glass: Check for metal wire oxidation rust spots (inferior products are prone to yellowing);

Laminated glass: Perspective testing of the uniformity of silk distribution to avoid local wrinkles;

Clip on glass: UV ink fade resistance (high-quality products>10 years).

4、 Technology Trends

Intelligent Composite: Dimming Glass+Laminated Silk Process, Achieving Dynamic Adjustment of Transmittance;

Environmental upgrade: Printing patterns with lead-free ink (compliant with RoHS standards).

Definition summary: A glass deep processing category that is based on sandwich safety structures and achieves functional expansion and artistic expression through differentiated embedded materials.

Wire, painted, silk glass

Category:

GLASS ENCYCLOPEDIA

Can frosted glass be cleaned with wet wipes?

→ Okay! Recommend using glass cleaner and fish scale cloth to avoid scratching the matte layer with hard objects.

How to choose between single-sided frosted and double-sided frosted?

→Single sided frosted (smooth surface facing inward) is easier to clean; Double sided frosted provides stronger privacy.

Will frosted glass reduce light transmittance?

→ It will decrease by about 20% -40%, and the ultra white glass substrate can reduce the loss of light transmission.

What are the common glass products in daily life?

Get A Quote

We will contact you within one working day. Please pay attention to your email.

Related Products