1、 Product Overview

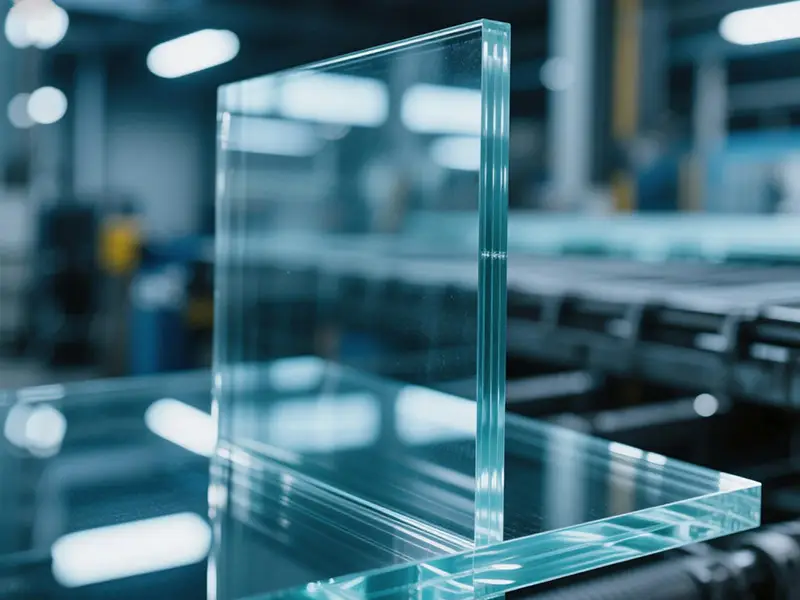

Insulating glass is a building glass product made by combining two or more pieces of glass with a highly airtight sealing material and a spacer material, forming a sealed dry gas space (filled with inert gases such as air or argon) in the middle. The core of its design lies in utilizing the low thermal conductivity of the gas layer to achieve insulation, sound insulation, and anti condensation functions, significantly improving building energy efficiency and comfort.

2、 Core structure composition

|

Components |

Materials and functions |

Technical points |

|

substrate |

Float glass/tempered glass/Low-E glass, etc., thickness 3-12mm |

Tempered substrate enhances safety (impact strength x 4) |

|

Spacer layer |

Aluminum alloy frame or composite material (including desiccant), thickness 6A/9A/12A (A=millimeters) |

Thickness ↑ → Thermal and Sound Insulation Performance ↑ |

|

SEALING SYSTEM |

Butyl adhesive (first leak proof)+polysulfide/silicone adhesive (second reinforced structure) |

Seal damage will result in functional failure |

|

Fill gas |

Dry air or argon gas (with a lower thermal conductivity than air) |

Argon filling improves insulation by approximately 15% |

3、 Core performance parameters

• Thermal insulation

Heat transfer coefficient (U value): 1.4-2.8W/㎡· K (single-layer glass ≈ 5.8W/㎡· K), energy-saving rate of 40-60%;

Sunshade coefficient: 0.38-0.76 (Low-E coating can adjust solar radiation heat).

• Soundproofing

High frequency noise is reduced by 30-40dB, and the weighted sound insulation can reach up to 45dB.

• Anti condensation

Dew point ≤ -40 ℃, can adapt to cold environments of -20 ℃.

4、 Classification and Application Scenarios

1. Classified by substrate material

Ordinary white glass Insulating: high cost-effectiveness (70-150 yuan/㎡), light transmittance ≥ 82% 4;

Tempered Insulating: Strong impact resistance (200-300 yuan/㎡), suitable for high-rise buildings;

Low-E Insulating: U value ≤ 1.8W/㎡· K (300-500 yuan/㎡), preferred for energy-saving buildings.

2. Applicable scenarios

|

Demand scenario |

Recommended configuration |

|

Heating in high-altitude regions |

12A or above argon filling layer+Low-E coating |

|

Residential areas with traffic noise |

Laminated Insulating composite structure (such as 6+1.52PVB+6+12A+6) |

|

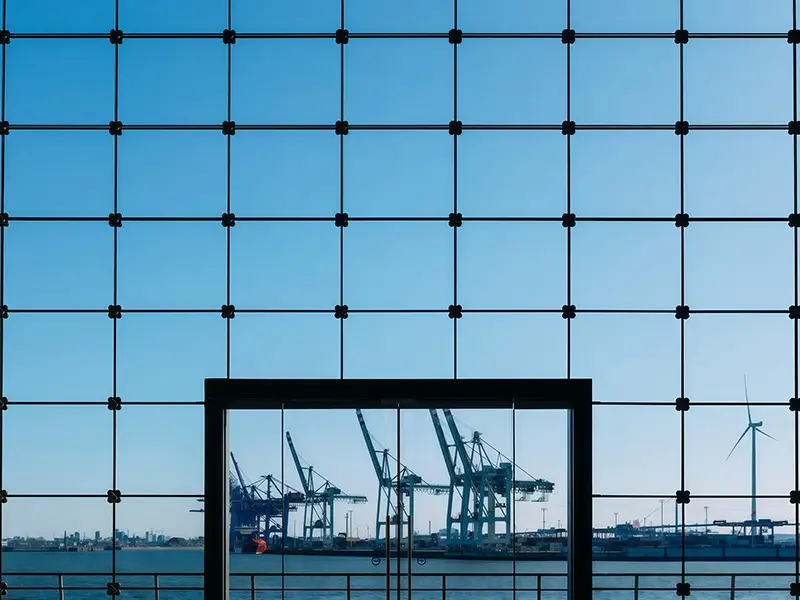

Commercial curtain wall |

Ultra white glass substrate+spacer layer above 20A |

5、 Comparison of performance with ordinary glass

| Performance |

Ordinary single-layer glass |

Insulating glass |

|

Heat transfer coefficient (U value) |

≈5.8W/㎡·K |

1.4–2.8W/㎡·K |

|

Isolation volume (Rw) |

≤25dB |

30–44dB |

|

Anti condensation ability |

Easy to frost (below 8 ℃) |

-No condensation at 40 ℃ |

| safety |

After fragmentation, it appears as a sharp piece |

Tempered version shattered into obtuse angle particles |

Selection suggestion: Choose cost-effective insulated glass for conventional buildings, and use composite configurations (such as laminated and insulated) in extreme weather or high noise areas

Insulating glass

Category:

GLASS ENCYCLOPEDIA

Can frosted glass be cleaned with wet wipes?

→ Okay! Recommend using glass cleaner and fish scale cloth to avoid scratching the matte layer with hard objects.

How to choose between single-sided frosted and double-sided frosted?

→Single sided frosted (smooth surface facing inward) is easier to clean; Double sided frosted provides stronger privacy.

Will frosted glass reduce light transmittance?

→ It will decrease by about 20% -40%, and the ultra white glass substrate can reduce the loss of light transmission.

What are the common glass products in daily life?

Get A Quote

We will contact you within one working day. Please pay attention to your email.

Related Products