Painted glass is a decorative glass formed by spraying specialized paint on the back of a glass substrate and curing it at high temperatures, which combines artistic expression and practical functions.

1、 Core Process and Classification

1. Manufacturing process

Coating methods: spray coating, roller coating, screen printing or spray coating, water-based environmentally friendly coatings (modified acrylic resin) are mainstream;

Curing process: Preheat at 50-80 ℃ and heat up to 160 ℃ for baking (3 hours). The paint film is chemically bonded to the glass for 28 hours;

Substrate selection: ordinary flat glass or tempered glass (to enhance safety).

2. Product classification

|

Type |

Feature |

|

Flat baking paint |

Smooth surface, glossiness>90%, bright colors (Pantone color card customization) |

|

Frosted baking paint |

Shading treatment on the back, transparent but opaque, enhances privacy |

|

Art baking paint |

Hand drawn patterns+high-temperature baking, suitable for customized decoration of churches and villas |

|

Functional baking paint |

Add nano coating (oil resistant, antibacterial) to achieve a hardness of 3H-4H |

2、 Core Performance and Parameters

• Physical characteristics

1. Adhesion: 0-1 level (cross cut test), resistant to 172 hours of ethanol immersion;

2. Hardness: 3H-4H pencil hardness, excellent wear resistance;

3. Environmental friendliness: formaldehyde/xylene free, RoHS certified.

• Functional advantages

1. Acid and alkali resistance, slip resistance, UV aging resistance;

2. Significant sound insulation effect (hollow composite structure sound insulation>32dB);

3. The transmittance can be adjusted (frosted version has a transmittance of 70% -85%).

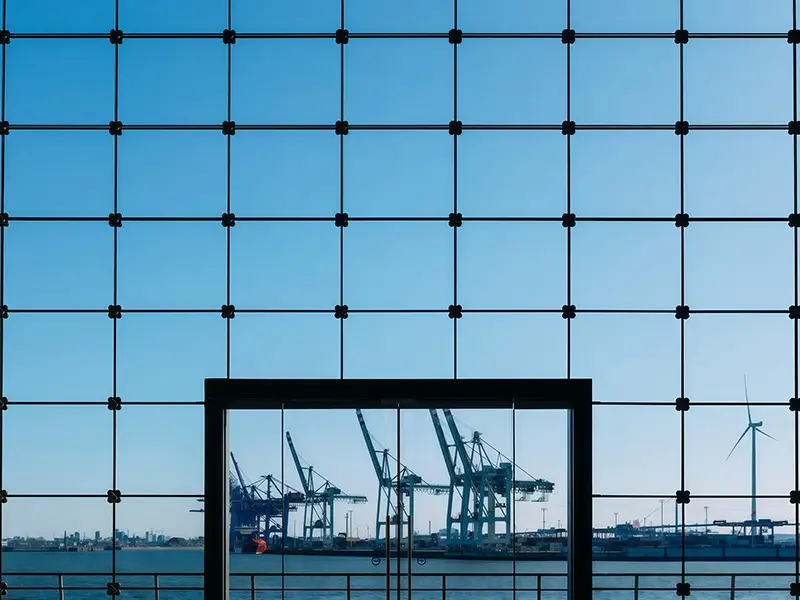

3、 Application scenarios and design adaptation

|

scene |

Recommended plan |

Key points |

|

Background wall |

Pearlescent/Polycrystalline Series (Size ≤ 2440 × 3660mm) |

Reserve expansion joints to prevent thermal expansion and contraction |

|

Kitchen countertop |

Tempered substrate+nano anti fouling coating |

Edge requires flow channel design to prevent water accumulation |

|

Commercial space |

Customized pattern baking paint (digital printing) |

Base material thickness ≥ 12mm to ensure load-bearing capacity |

|

Bathroom partition |

Matte laminated baked paint glass (reinforced with explosion-proof film) |

Prioritize choosing IP68 waterproof motor models |

Construction specifications:

Installation error ≤ 2mm, weather resistant adhesive filling gap ≥ 8mm;

The glass thickness of high-rise buildings should be ≥ floor height ÷ 10 (if there are 30 floors, it should be ≥ 3mm).

4、 Notes and Trends

• Precautions:

(1) The naturally dried paint surface is prone to peeling off, and high-temperature baking technology is preferred;

(2) The concave convex surface is difficult to clean, and the flat nano coating is more practical;

• Technological Trends:

(1) Mainstream by 2025: Photovoltaic composite baked paint glass (power generation+decoration);

(2) Intelligent dimming+baking paint process, achieving dynamic light transmission adjustment

Painted glass

Category:

GLASS ENCYCLOPEDIA

Can frosted glass be cleaned with wet wipes?

→ Okay! Recommend using glass cleaner and fish scale cloth to avoid scratching the matte layer with hard objects.

How to choose between single-sided frosted and double-sided frosted?

→Single sided frosted (smooth surface facing inward) is easier to clean; Double sided frosted provides stronger privacy.

Will frosted glass reduce light transmittance?

→ It will decrease by about 20% -40%, and the ultra white glass substrate can reduce the loss of light transmission.

What are the common glass products in daily life?

Get A Quote

We will contact you within one working day. Please pay attention to your email.

Related Products