Curtain wall glass is a non load bearing external wall maintenance system composed of glass panels and metal frames. It achieves displacement ability relative to the building main body through suspended installation, and has both decorative and functional functions.

1、 Core definition and structural characteristics

Definition

1. Non load bearing exterior wall system: composed of glass panels and aluminum alloy/steel frame, does not bear the load of the main structure;

2. Suspended installation: Fixed to the main structure through connectors, allowing for slight displacement to resist wind loads and seismic effects.

Structural composition

|

Components |

Functional requirements |

|

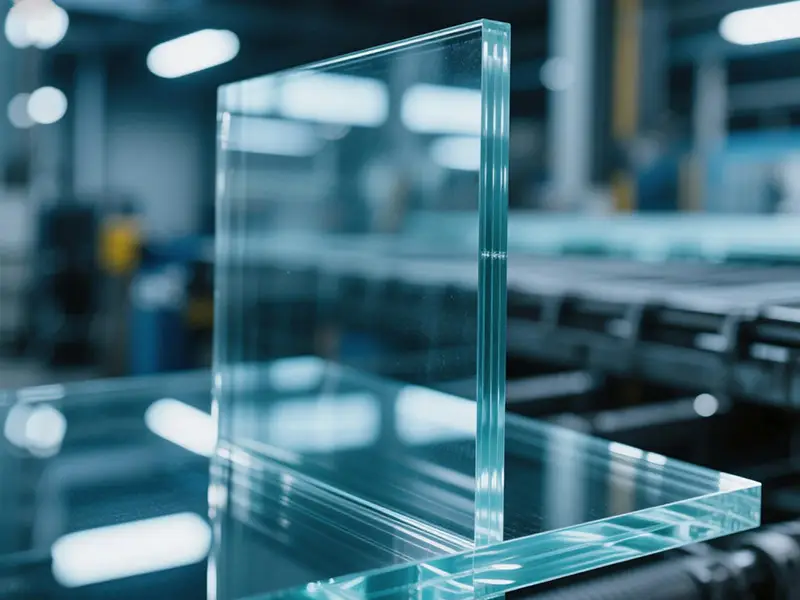

glass panel |

Thickness 6-10mm (hollow structure) |

|

Supporting frame |

Aluminum alloy or steel keel, capable of withstanding wind pressure and self weight |

|

SEALING SYSTEM |

Silicone structural adhesive/elastic pad ensures airtightness and seismic resistance |

2、 Type and process characteristics

1. Classify by structural form

| type |

Technical features |

Applicable scenarios |

| Clear frame curtain wall |

Exposed metal frame, mechanically fixed glass, strong deformation resistance |

Traditional architecture, high wind pressure areas |

| Hidden frame curtain wall |

The frame is hidden inside the glass and relies on structural adhesive for load-bearing |

Modern minimalist style facade |

|

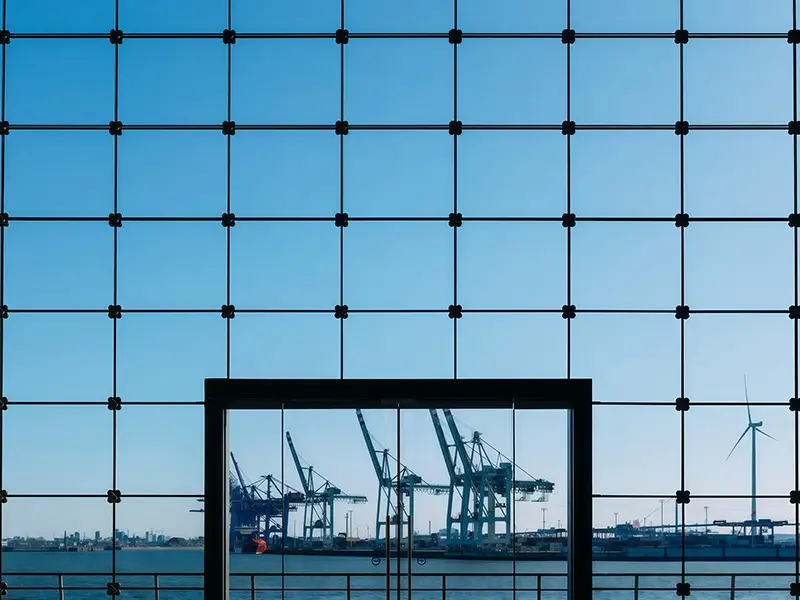

Full glass curtain wall |

Glass ribs+panel load-bearing, excellent transparency (glass ribs ≥ 12mm thick) |

Lobby and skylight |

|

Point supported curtain wall |

The metal claw is fixed at a single point and needs to be made of tempered glass |

Art installations, large public spaces |

2. Key process specifications

Mandatory application of safety glass: Frame supported curtain walls must use tempered/laminated glass, and point supports must use tempered products;

Installation accuracy: Glass groove depth ≥ 24mm (including 17mm profile groove+7mm cushion block);

Energy saving design: The hollow structure is filled with inert gas, and the composite Low-E coating can improve insulation by 40%.

3、 Performance and safety requirements

• Core indicators

Anti wind pressure deformation: Structural stability needs to be verified through wind tunnel tests;

Thermal performance: Heat transfer coefficient in cold regions ≤ 1.9-2.0 W/(㎡· K);

Light pollution control: Reflectance should be ≤ 0.30, and sensitive areas should be ≤ 0.15.

• Prevention of safety hazards

Avoid concave design: prevent burning accidents caused by focused strong light (such as the 117 ℃ spotlight in the London Radio Tower);

Regular maintenance: Aging glass curtain walls need to be tested for the risk of cracking (the inner layer of double-layer curtain walls is prone to failure after the outer layer ruptures);

Anti detachment design: In humid areas, the sandwich process is preferred (waterproof>crystal plating).

4、 Selection and Application Trends

| Scenario requirements |

Recommended plan |

Case |

| Super high-rise buildings |

Laminated hollow coated glass (such as Shanghai Global Financial Center) |

Balancing safety and visual transparency |

|

Energy saving renovation |

Hollow Low-E coated glass (heat transfer coefficient ↓ 40%) |

Exterior facade in cold regions |

|

Artistic facade |

Point supported full glass curtain wall+dynamic lighting system |

Museum and commercial entrance |

Technological Trends:

Intelligent temperature control coating: anti fogging in high-altitude areas;

Self repairing TPU substrate: enhances scratch resistance (such as Mr. Glass's ice armor glitter film).

5、 Maintenance and Regulations

• Mandatory regulations

Safety standards: comply with the impact resistance requirements of GB 15763.2-2025 Safety Glass for Building Use;

Environmental certification: detection of heavy metal precipitation (ISO 14001).

• Maintenance points

Cleaning: Neutral solvent+microfiber cloth, strong alkaline cleaning agents are prohibited;

Maintenance cycle: Annual inspection of adhesive joint aging and glass rib adhesion.

Attachment: Minimum Thickness Requirements for Curtain Wall Glass

Building exterior windows: ≥ 5+12A+5mm insulated tempered glass;

Curtain wall engineering: ≥ 6+12A+6mm insulated tempered glass

Curtain wall glass

Category:

GLASS ENCYCLOPEDIA

Can frosted glass be cleaned with wet wipes?

→ Okay! Recommend using glass cleaner and fish scale cloth to avoid scratching the matte layer with hard objects.

How to choose between single-sided frosted and double-sided frosted?

→Single sided frosted (smooth surface facing inward) is easier to clean; Double sided frosted provides stronger privacy.

Will frosted glass reduce light transmittance?

→ It will decrease by about 20% -40%, and the ultra white glass substrate can reduce the loss of light transmission.

What are the common glass products in daily life?

Get A Quote

We will contact you within one working day. Please pay attention to your email.

Related Products