Low-E glass (low emissivity glass) is a functional glass that achieves energy saving by coating multiple layers of metal or compound films on the surface of the glass.

1、 Core principles and technical characteristics

•Energy saving mechanism

Infrared reflection: Surface coating (silver, metal oxide) with emissivity ≤ 0.15 (ordinary glass 0.84), reflecting 80% of solar infrared heat in summer, blocking indoor heat leakage in winter, achieving "warm in winter and cool in summer";

Transparency: Visible light transmittance of 0% -95%, high transparency (>70%) ensures natural lighting, and low transparency (<50%) enhances shading.

•Core classification

|

Type |

film structure |

Applicable scenarios |

|

Single silver Low-E |

1 layer of silver+compound, a total of 5 layers |

Residential doors and windows, basic energy-saving |

|

Double Silver Low-E |

2 layers of silver+compound, a total of 9 layers |

Commercial curtain wall, high energy-saving demand |

|

Three Silver Low-E |

3 layers of silver+compound, ≥ 13 layers |

Super high-rise buildings, ultimate energy efficiency |

Performance parameter comparison

|

Indicator |

Low-E glass |

Ordinary glass |

|

Thermal conductivity coefficient |

1.6–1.9 W/(m²·K) |

2.3–5.8 W/(m²·K) |

|

Shading Coefficient |

0.18-0.47 (efficient heat resistance in summer) |

0.8–0.9 |

|

UV barrier |

75% -95% (fade resistant) |

About 30% |

2、 Production process and technological innovation

• Manufacturing process

Offline sputtering method: Vacuum magnetron sputtering coating, with diverse film layers and strong energy efficiency, but not suitable for hot bending processing;

Online vapor deposition: synchronous coating on float production line, can be tempered but has weak heat reflection performance.

• Technological upgrade

Photovoltaic integration: New Low-E glass combined with power generation function by 2025, suitable for low-carbon buildings;

Intelligent dimming: The coating layer is linked with an electronic control system to dynamically adjust the transmittance.

3、 Application scenarios and selection suggestions

|

Scene |

Recommendation |

precautions |

|

Residential doors and windows |

Single silver high transparency type (transmittance>70%) |

Northern preferred low heat transfer coefficient model |

|

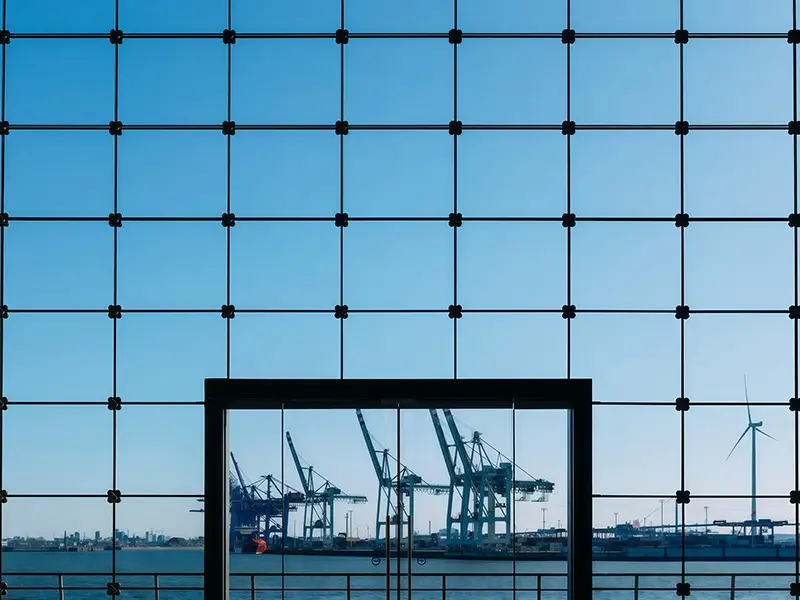

Commercial curtain wall |

Double silver/triple silver hollow composite |

Thickness ≥ 12mm, wind resistance |

|

Western sun wall |

Low transparency type (shading coefficient<0.5) |

Paired with an external sunshade system |

Low-e glass

Category:

GLASS ENCYCLOPEDIA

Can frosted glass be cleaned with wet wipes?

→ Okay! Recommend using glass cleaner and fish scale cloth to avoid scratching the matte layer with hard objects.

How to choose between single-sided frosted and double-sided frosted?

→Single sided frosted (smooth surface facing inward) is easier to clean; Double sided frosted provides stronger privacy.

Will frosted glass reduce light transmittance?

→ It will decrease by about 20% -40%, and the ultra white glass substrate can reduce the loss of light transmission.

What are the common glass products in daily life?

Get A Quote

We will contact you within one working day. Please pay attention to your email.

Related Products